Coal wastes: handling, pollution, impacts, and utilization

2023.1.1 Sources and types of coal wastes. Considering the operational and technological processes employed and their technical characteristics, wastes generated from the coal mining industry are usually classified into three categories: (1) mining

More

Occurrence of Minerals in Coal and Its Geological

The precombustion washing and washability of coal are increasingly gaining attention as a clean coal technology in China. In this study, the raw coal was collected from different

More

Prospects for Cleaner and More Efficient Coal Production

2016.11.8 efficiency-enhancing coal technologies; coalbed methane recovery and utilization; coal gasification; coal liquefaction; and carbon capture and storage. The

More

Minerals Free Full-Text Washability and Distribution

Generally, coal washing is conducted to remove minerals from the Run-of-Mine (ROM) coal, with the purpose of improving the coal quality and reducing the emissions of

More

Migration behaviors of arsenic and sulfur from coal during washing ...

2022.7.1 Two raw coals and their washery products were collected from two coal-washing plants of Ningwu coal field, Shanxi, China. The migration behaviors of sulfur (S)

More

11.10 Coal Cleaning - US EPA

2015.9.10 11.10.1 Process Description1-2,9 Coal cleaning is a process by which impurities such as sulfur, ash, and rock are removed from coal to upgrade its value. Coal

More

A systematic review exploring the utilization of coal mining

2023.3.3 During open cast mining, coal can be extracted only after removing layers of soil and rock over it, often termed as over burden (OB). Similarly, coal tailing is another

More

Advances in the chemical leaching (inorgano

2019.5.24 So cleaning of coal through physical or chemical processes becomes utmost important. There are several coals which cannot be cleaned by physical beneficiation techniques to produce low ash

More

Coal Cleaning - an overview ScienceDirect Topics

Coal Cleaning. Coal cleaning is an option for removing mercury from the coal prior to utilization. Of the more than 1 billion short tons of coal mined each year in the United

More

Coal Preparation by the Air-Sand Process J. Fluids Eng.

2023.2.10 The author presents in this paper the features of an air-sand process for the preparation of coal by specific-gravity separation. In this process, the float-and-sink

More

Basic knowledge about coal preparation - LinkedIn

2017.6.29 agglomeration or briquetting. Coal preparation process starts with crushing and screening of freshly mined coal, which removes some of the non-coal material. Mechanical cleaning or “washing ...

More

The efficacy of soil washing for the remediation of per- and

2023.3.5 The SWP used to treat the PFAS-contaminated soils in this study consisted of a proprietary process developed by Ventia Services Pty Ltd, Sydney Australia and CleanEarth Technologies Inc., Halifax, Nova Scotia, Canada – called SourceZone® and has a site footprint of ∼2000 m 2.A detailed overview of the process is shown in Fig. 1, and in

More

Conventional and recent advances in gravity separation

2023.1.21 Separation technologies to remove gangue minerals and impurities in coal are based on mineral processing technologies and a summary of the largest mines in top 5 countries of coal production including production, reserves, coal types, impurities, mining methods, and coal cleaning processes were shown in Table 3. In some coal mines where

More

Minerals Free Full-Text Washability and Distribution

The float-sink test is a commonly used technology for the study of coal washability, which determines optimal separation density for coal washing based on the desired sulfur and ash yield of the cleaned coal. In this study, the float-sink test is adopted for a high-sulfur Late Permian coal from Hongfa coalmine (No.26), southwestern Guizhou, China, to

More

Prospects for Cleaner and More Efficient Coal Production

2016.11.8 efficiency-enhancing coal technologies; coalbed methane recovery and utilization; coal gasification; coal liquefaction; and carbon capture and storage. The assessment revealed that most countries in NEA have placed a relatively high priority to the development of cleaner and more efficient coal technologies, from the upstream to the

More

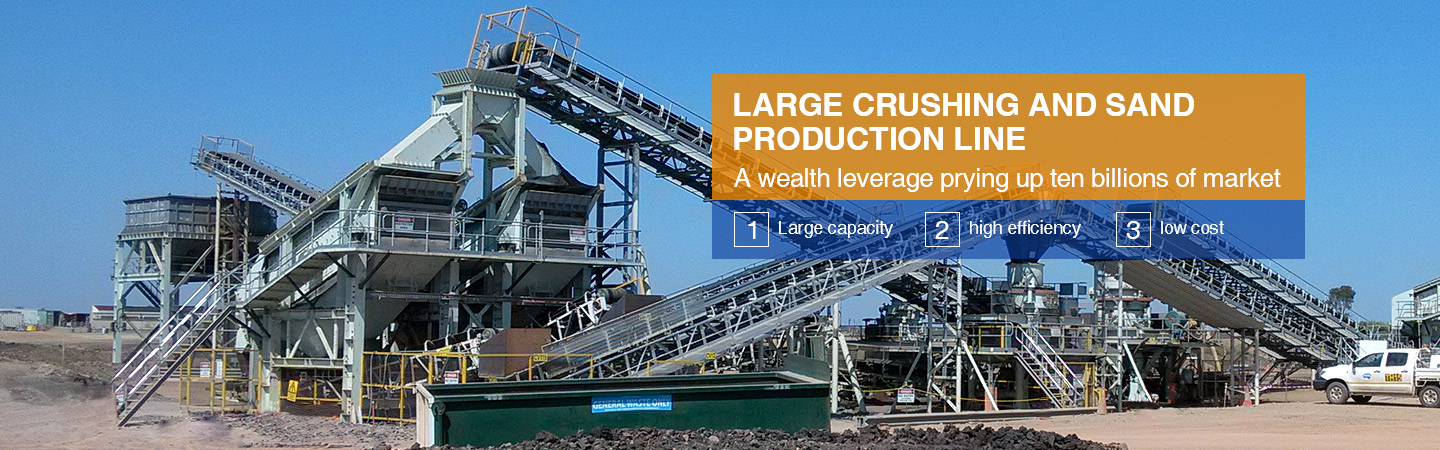

Can coal gangue be used to make sand? - LinkedIn

2021.11.8 The sand made from coal gangue meets the sand use standard. The hardness value of coal gangue is about 3, and the compressive strength ranges from 300 to 4700pa. The long-term production practice ...

More

Migration behaviors of arsenic and sulfur from coal during washing ...

2022.7.1 Coal washing process is the basic technology for coal quality improvement, which can obtain the cleaned coal and enrich the harmful elements in coal gangue [4–6] . Li et al. [7] pointed out that S in coal was mainly existed in the form of pyrite S, sulfate S and organic S. Qi et al. [8] reported that most pyrite S and a small amount of ...

More

McLanahan Sand Washing Plants

Why McLanahan Sand Washing Plants. Sand Washing comes in many forms and covers a range of feed and products produced, including construction aggregates such as concrete, asphalt, mason, mortar, and plaster sands; sports sands such as for golf courses, ball parks, and race courses; industrial sands, such as glass, filter, foundry, and frac; specialty

More

A systematic review exploring the utilization of coal mining

2023.3.3 Similarly, coal tailing is another type of unproductive waste produced during the preparation and washing phase of coal mining [7]. Tailings are usually disposed of by pumping and deposited in the form of an aqueous slurry. ... Sand is the predominant constituent of coal wastes, responsible for its abrasive nature, and helps in free draining ...

More

Heavy Media Separation Process - 911 Metallurgist

2016.5.22 These processes include the Chance sand-flotation process, the Vooys barite-and-clay process, and the Wuensch process. Chance Process. For cleaning coal, the Chance process has been in use for about 20 years. The medium consists of a suspension of sand in water. The sand must be of relatively uniform size, — 40 + 80-mesh being

More

Dewatering of fine coal and refuse slurries-problems

2009.9.1 6 th International Conference on Mining Science Technology Dewatering of fine coal and refuse slurries-problems and possibilities B. K. Parekh Center for Applied Energy Research, 2540 Research Park Drive, Lexington, KY 50511, USA Abstract Dewatering of fine clean coal and refuse slurry is one of the most important aspects of

More

Integrated green mining technology of “coal mining-gangue washing ...

2021.8.24 In Tangshan Mine, there are four engineering problems, including the layout of multiple seam mining system, serious environmental damages caused by gangue accumulation and surface collapse, nearly 100 million tons of three under coal (coal trapped under buildings, water bodies, and railways) to be released, and the control accuracy of

More

(PDF) Coal washing scenario in India and future

2016.6.28 India has proven reserves of coal amounting to ∼126 billion tonnes out of which ∼18 billion tonnes is metallurgical or coking coal, ∼107 billion tonnes is thermal coal, and ∼1 billion ...

More

Review on treatment technologies of coal gasification wastewater

2022.1.20 1. Introduction. Coal gasification generally refers to an incomplete reaction between various coal (coke) and oxygen-carrying gasification agents (O 2, H 2 O, CO 2), and finally produces a gas composed of CO, H 2, CO 2, CH 4, N 2, H 2 S, COS etc (Fan et al., 2019).Coal gasification technology is the core of clean and efficient conversion of

More

Oil Contaminated Sand: An Emerging and Sustainable Construction ...

2015.1.1 Due to prohibitive cost of cleaning and disposing oil contaminated sand, mixing and stabilising them with cement and using them in construction is now considered as an alternative and cheap remediation method. ... “A white paper describing produced water from production of crude oil, natural gas, and coal bed methane,” prepared by

More

Recovery of coal particles from a tailing dam for

2018.2.22 Considerable amounts of coal particles are accumulated in the tailing dams of washing plants which can make serious environmental problems. Recovery of these particles from tailings has economically and environmentally several advantages. Maintaining natural resources and reducing discharges to the dams are the most

More

Coal wastes: handling, pollution, impacts, and utilization

2023.1.1 Sand, silt, and clay: Yagüe et al. (2018) Jisan (China) Siltstone carbonaceous mudstone: Jiang et al. (2015) Wugou (China) Siltstone: Jiang et al. (2015) ... After sampling the coal waste material from the Alborz Markazi coal washing plant situated in Mazandaran province in the north of Iran, the coal waste was treated to be used as a

More

The History of Dewatering Screens: From Gold to Coal to

2021.1.21 So much so, that the company introduced the screen to the coal industry for: Raw coal caking, which focused on providing a consistent moisture product ahead of water-sensitive cleaning processes such as heavy media cycloning. Jig product dewatering. Spiral discharge (clean coal) dewatering. Preparation of fine coal (-28 mesh) prior to

More

Why does coal gangue make sand? Where's the good Sand

2020.3.3 Coal gangue is a solid waste discharged during coal mining and coal washing. It is a dark gray rock with lower carbon content and harder than coal. ... sand processing plant / planta de ...

More

Design and implementation of a coal-dust removal device for heavy

2020.9.10 The coal-dust removal efficiency reached approximately 20 t/h. The devices greatly improve the efficiency of coal-dust removal in the tunnels, improved the operating environment, relieved the burden of workers and solved the problem of coal-dust pollution in the tunnel. Figs 6 – 8 show the effects.

More