Lime Shaft Kilns - ScienceDirect

2017.8.1 The most efficient and ecological way to calcine limestone and dolomite is the use of modern shaft kilns. The requirement to install new lime shaft kilns at a stagnating market growth is substantial because a significant amount of lime is still

More

(PDF) Lime Shaft Kilns - ResearchGate

2017.8.1 Abstract is substantial because a significant amount of lime is still produced with outdated kiln models. More than three quarters of s

More

(PDF) Energy optimisation of vertical shaft kiln

2018.9.1 Several different options were analyzed: (a) preheating of a raw material, (b) preheating of heavy fuel oil, (c) preheating of

More

FUNDAMENTAL APPROACH TO THE DESIGN OF VERTICAL SHAFT

The merits of vertical shaft kiln include: Simplicity of construction and operation Low initial cost High thermal efficiency High volumetric efficiency Minimum decrepitation of solid

More

Optimisation of combustion and technology process in

2017.10.4 This work is based on energy and exergy analysis of the operation of a vertical shaft kiln, with the aim to identify the factors

More

High-Temperature Shaft Kiln FLSmidth

The hottest shaft kiln on the market. This sintering kiln is designed to achieve the high product quality the refractory industry demands, while also having the flexibility to

More

ENERGY OPTIMISATION OF VERTICAL SHAFT KILN OPERATION IN

Energy Optimisation of Vertical Shaft Kiln Operation THERMAL SCIENCE: Year 2018, Vol. 22, No. 5, pp. XXXX-XXXX 1 ... [14] compares the advantages of modern shaft

More

VERTICAL SHAFT BRICK KILN

VERTICAL SHAFT BRICK KILN DESIGN MANUAL A Practical Guide On how to design a Vertical Shaft Brick Kiln. Contact Details: Technology and Action for Rural

More

process in a vertical shaft kiln Dolomite - ResearchGate

the technology process. exhaust. In a vertical (shaft) kiln, the dolomite, as it flows downward by gravity, passes through three operating zones: (1) preheating, (2) reaction

More

KILNS

2011.2.2 In general, the word "kiln" is applied to devices for thermal processing of nonmetallic solids, and is particularly associated with the ceramic, cement and lime industries. The three principle types are

More

Refractories for Lime Calcination SpringerLink

2020.11.29 The quality of the calcined lime and the energy efficiency of calcination depend upon the design of the kiln. 5.3.1 Single Shaft Kiln. This kiln design consists of vertical tubular shell of 2–7 m diameter and up to 28 m high fitted with small open top with automatic feeding, and air is blown through larger bottom opening.

More

Detailed Guide: The Evolution of Vertical Shaft Kiln Technology

2023.2.15 The evolution of vertical shaft kiln technology has had a significant impact on the lime industry, both in terms of production costs and product quality. Vertical Shaft kilns are generally simpler and more affordable to build and operate than rotary kilns, making them an attractive option for small-scale producers and entrepreneurs.

More

modern discharege of vertical shaft kiln

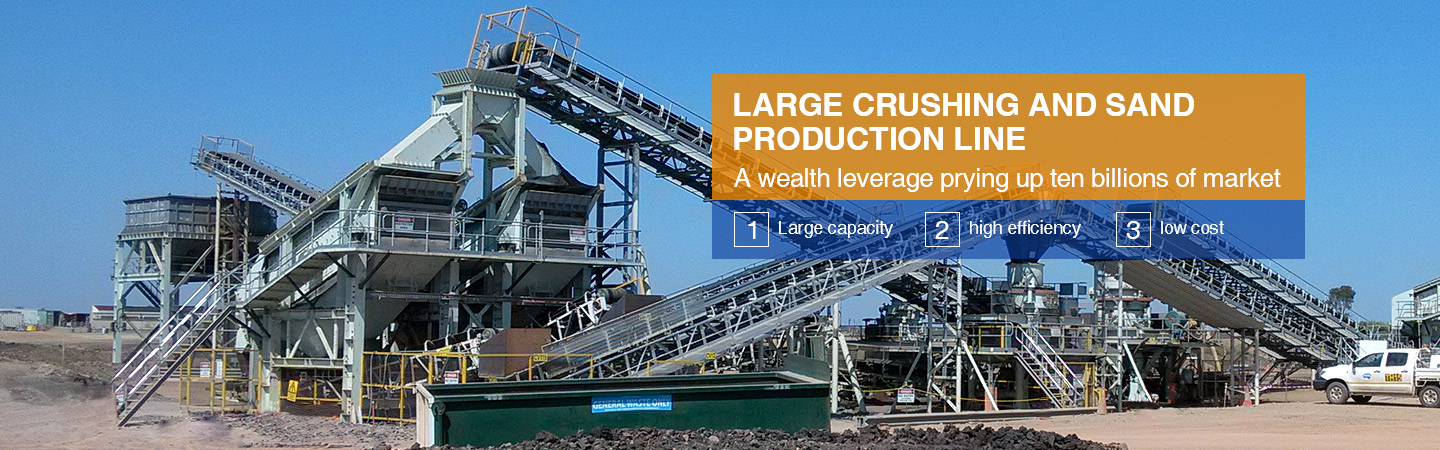

Products. AS a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any size-reduction requirements, including quarry, aggregate, grinding production and complete stone crushing plant.

More

(PDF) Energy optimisation of vertical shaft kiln operation in the ...

Filkoski, R. V., et al.: Energy Optimisation of Vertical Shaft Kiln Operation in THERMAL SCIENCE: Year 2018, Vol. 22, No. 5, pp. 2123-2135 2123 ENERGY OPTIMISATION OF VERTICAL SHAFT KILN OPERATION IN THE PROCESS OF DOLOMITE CALCINATION by Risto V. FILKOSKI a*, Ilija J. PETROVSKI a, and Zlatko GJURCHINOVSKI b a

More

(PDF) Energy optimisation of vertical shaft kiln operation in the ...

2018.9.1 Energy Optimisation o f Vertical Shaft Kiln Operation in 2128 THERMAL SCIENCE: Year 2018, Vol. 22, No. 5, pp. 2123 - 2135 The raw dolom it e comp osit ion is 54.3% C a-

More

Comprhensive Industry Document On Vertical Shaft Kiln Based

COMPREHENSIVE INDUSTRY DOCUMENT ON VERTICAL SHAFT KILN. BASED MINI CEMENT PLANTS. CONTENTS Fig. 3 Lurgi Sinter Grate . the material as the kiln rotates at 1 to 2 rpm. Various chemical reactions (Calcination, sintering, cooling) takes place as the material temperature goes upto 1440°C. Hot gases having transferred the heat to

More

Publications - Cement Kilns: Audit Report of Two Cement Plants in ...

A rotary cement kiln at one cement manufacturing facility (referred to as Shui Ni 1 in this report) and a vertical shaft kiln at another cement manufacturing facility (referred to as Shui Ni 2 in this report), which are both in Shandong Province, were selected to conduct the energy and emission assessments through

More

process in a vertical shaft kiln Dolomite - ResearchGate

shaft kiln and cross-section of a vertical shaft kiln. (a) Preheating zone; (b) Reacting zone; (c) Cooling zone Fig. 5. ... before discharge from the bottom of the kiln.

More

modern discharge of vertical shaft kiln - MC World

Modern kilns are typically one of three designs: single shaft, annular, or regenerative Each respective design is progressively more energy efficient, but all are based on a countercurrent flow of hot air Energy Optimisation o f Vertical Shaft Kiln Operation in 2128 THERMAL SCIENCE: Year 2018, Vol 22, No 5, pp 2123 2135 The raw dolom it e comp

More

modern discharege of vertical shaft kiln

Products. AS a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any size-reduction requirements, including quarry, aggregate, grinding production and complete stone crushing plant.

More

(PDF) Lime Shaft Kilns - ResearchGate

2017.8.1 Figure 10 shows the functional principle of the PFR kiln and illustrates the two phases of the gas flow. Lime is discharged continuously at the bottom end of the kiln shafts. Fuel is only fed into ...

More

MODERN DISCHAREGE OF VERTICAL SHAFT KILN

Kiln And Raw Mill 33 Modern Discharege Of Vertical Shaft Kiln And Raw Mill 33 Modern Discharege Of Vertical Shaft Kiln. Aug 01 2017 The potential to install new modern PFR lime shaft kilns for product category 1 at low or stagnating market growth is still substantial because today the number of modern PFR lime shaft kilns is less than

More

kiln and raw mill 33 virtical shaft kiln cement

kiln and raw mill 33 virtical shaft kiln cement. kiln and raw mill 33 sizing of cement rotary kiln Raw mill capacity for tpd kiln SEW Gears offering 500 TPD Rotary Kiln Tyre, Capacity: 100 To 600 Tpd at Rs set in Ghaziabad, Uttar Pradesh Get best price and read about pany and get Oline Chat Cement clinker grinding ball mill capacity 2000 tp

More

modern discharege of vertical shaft kiln

Taconite Ore ProcessingThe History of Concrete Textual. W Grate/kiln furnace feed 3 03 023 49 AZ Vertical shaft furnace discharge 3 03 023 70 BA Straight grate furnace discharge 3 03 023 80The History of Concrete The beginning of the era of portland cements of modern Vertical shaft kilns were replaced with rotary kilns and ball mills

More

ENERGY OPTIMISATION OF VERTICAL SHAFT KILN OPERATION

Energy Optimisation of Vertical Shaft Kiln Operation THERMAL SCIENCE: Year 2018, Vol. 22, No. 5, pp. XXXX-XXXX 1 ... [14] compares the advantages of modern shaft kilns with other kiln

More

ENERGY OPTIMISATION OF VERTICAL SHAFT KILN OPERATION

Energy Optimisation of Vertical Shaft Kiln Operation THERMAL SCIENCE: Year 2018, Vol. 22, No. 5, pp. XXXX-XXXX 1 ... [14] compares the advantages of modern shaft kilns with other kiln

More

Optimisation of combustion and technology process in a vertical shaft kiln

2017.10.4 The main geometry data of the kiln are given in tab. 1 [21, 22]. The main data defining the kiln capacity are as follows: the raw material (dolomite) consumption is 6.7 t/h and the The raw ...

More

Vertical Shaft Lime Kiln for Cement Plant

Active lime vertical kiln equipment supporting. Calcination of limestone Qualified limestone goes to the top of the preheater through the belt conveyor, and the material is introduced into the body of the preheater from the silo at the top of the preheater through the discharge chute, and at the same time, the high-temperature flue gas from the rotary kiln preheats

More

Vertical Shaft Kiln - AGICO Cement Plant

Vertical Shaft Kiln Solutions. 1. Traditional VSK: Clinker output capacity from 60TPD to 400TPD. 2. Patented AC VSK: Clinker output capacity from 500TPD to 1000TPD. 3. Patented Differential VSK: Clinker output capacity from 700-1500TPD. After years of research and improvement on cement shaft kilns by our technical research and

More